Bridgeport Transportation and Land Use Study Receives Planning Award

HRG was part of a team that was honored this week at the Places 2040 Planning Leadership Awards. Our project, the Bridgeport Transportation and Land Use Study, was recognized in the Thinking Beyond Borders category. Thinking Beyond Borders is one of five “Big Ideas” in Lancaster County’s comprehensive plan (otherwise known as places2040). It promotes cooperation across traditional boundaries to achieve regional goals, and the Bridgeport Transportation and Land Use Study exemplifies this approach.

Bridgeport began as a historic village and gateway for travel between Lancaster’s city neighborhoods and its rural landscapes, dating as far back as the 1800s. Today, it encompasses portions of four municipalities: the City of Lancaster and East Lampeter, West Lampeter, and Lancaster Townships. These four municipalities worked together on a shared vision for the area’s transportation infrastructure, trails, and land use policies in order to enhance walkability, reduce congestion, and create vibrant spaces for the community to enjoy.

HRG provided transportation planning services and cost estimates for the creation of this study. Derck & Edson led public engagement and provided streetscape and land planning services. Town Planning Partnership, LLC, assisted with land planning and public engagement. All municipalities and the Lancaster County Planning Department provided representatives for the steering committee. Over 800 local community members provided essential input/feedback as part of the planning effort.

We’re humbled to be recognized among so many great projects at the Places 2040 award ceremony, and we’re thankful for the opportunity to be a part of this project team.

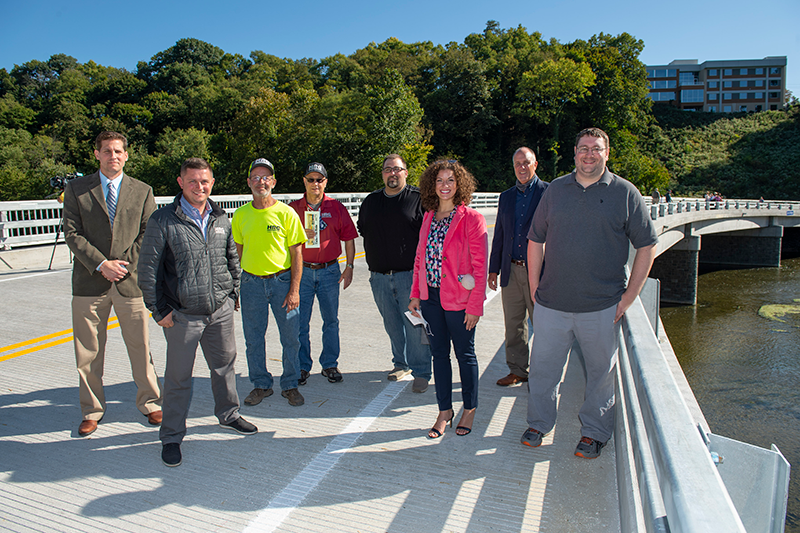

(L-R) Bob Shenk, Steve Hackett (Derck & Edson), Ryan Hostetter (HRG), Cindy McCormick (City of Lancaster), Tara Hitchens (East Lampeter Township), Mark Evans (Derck & Edson, Town Planning Partners), Terry Martin (Lancaster County Planning Commission), Ben Bamford (Lancaster County Planning Commission)

Steve Malesker recently joined HRG as a senior project manager in our Transportation Group. He is responsible for bridge design and inspection projects throughout the south-central counties of Pennsylvania.

Steve Malesker recently joined HRG as a senior project manager in our Transportation Group. He is responsible for bridge design and inspection projects throughout the south-central counties of Pennsylvania.

Herbert, Rowland & Grubic, Inc. (HRG) is pleased to announce that Jeffrey A. Mikesic, P.E., has been promoted to practice area leader for the firm’s Transportation Group.

Herbert, Rowland & Grubic, Inc. (HRG) is pleased to announce that Jeffrey A. Mikesic, P.E., has been promoted to practice area leader for the firm’s Transportation Group.