Get to know our construction phase services team!

/in Uncategorized /by Judy LincolnThe Master Builders Association and others are celebrating Construction Week October 15 -20, and we wanted to join the celebration by spotlighting our talented resident project representatives and construction inspectors. These men and women deliver real value by monitoring construction activities and ensuring the finished project accurately reflects the design plans our clients approved. Their work saves time and money, and we relish the opportunity to promote them this week!

Terry Meek

Terry Meek is a resident project representative in our Harrisburg civil group. He typically spends his day traveling between construction sites around Central PA, performing inspections. His job involves new faces and new places on a regular basis, working with various contractors in different locations around the city. It’s this variety that he loves the most, but being outside is a close second.

“I’ve always enjoyed being outside,” Terry says, “and I’ve always enjoyed being around construction equipment.”

He joined HRG in 2012, but he’s been in the industry for 16 years. His first job involved assignments throughout the southern portion of the East Coast, from D.C. to Savannah, Georgia. One of the more memorable projects was at a landfill site in Charleston, South Carolina, which had alligators swimming in various ponds.

Whatever the project, Terry is committed to ensuring quality construction for our clients. He’s also committed to finding ways to save time and money on their behalf.

Gary Rapp

Gary Rapp is a resident project representative in our Harrisburg civil group. He rises early to get a head start on the day, visiting construction sites to verify all M&P controls are in place. Then he completes PSA’s at the project office, meets with contractors, and spends the rest of the day inspecting construction activities.

He’s currently working on improvements to the Capital Area Greenbelt. He also worked on the award-winning Craighead Bridge replacement in Cumberland County and streetscape improvements in Middletown Borough, but these are just two of many projects he’s completed over the past 10 years working with HRG.

A recommendation from a friend brought him to a career in construction inspection, but his pride in the finished project is what has made him stay all these years, “My favorite part of construction is seeing the completed project when work is done. Whether it’s a streetscape that revitalizes the neighborhood or a new bridge that improves safety, it gives me great pride to play a role in those improvements.”

Ryan Sekerski

Ryan is a resident project representative in our Pittsburgh water and wastewater group. He observes the construction of water and sewer system projects, acting as a liason between the contractor, the engineers, and the client. He makes sure that all items on the final design plan are completed, reports any discrepancies or modifications, and tracks ongoing progress.

His favorite part of working in construction is being outdoors – even in the coldest days of winter. “I love snow,” he says. “Working outdoors during a heavy snow reminds you of being a kid again when you loved to go out and play!”

He’s been involved in construction since high school when he started working for a highway paving contractor. Since then, he’s worked for a variety of engineering firms and local municipalities.

Over the years, he’s completed a diverse array of projects, and it’s hard for him to pick just one favorite. Working in the field allows him to see and experience many different sections of the city, eating at local diners and small mom and pop shops. It also allows him to meet people from all walks of life.

“I like meeting new people,” he says. “They like to come out and talk to you when you’re working near their homes. Sometimes the people and their stories are the most interesting part of the job.”

With almost 30 years of experience in construction and almost 18 as an inspector, Ryan has seen a lot of challenges in the field. His experience helps him keep a cool head because he’s learned every problem has a solution if you think it through one step at a time.

Eric Lincoln

Eric is a resident project representative for the civil service group in our Harrisburg office. He assists many of our municipal clients by reviewing land development plans for compliance with local ordinances and observing land development activity to verify the work is being completed according to the plans and regulatory standards. He also observes construction of municipal infrastructure like storm sewers, collection systems, curbing and sidewalks, roadways and paving, retaining walls, and more.

Prior to joining HRG, he served the state of Maryland as a resident maintenance engineer in Eastern Baltimore County. His responsibilities included maintaining more than 500 miles of highway with an emphasis on emergency management, logistics, and maintaining fiscal accountability.

Today, a typical day on the job is characterized by “coffee, people, and construction site challenges,” according to Eric. He loves the opportunity to work with individuals that have varying skills and expertise and see how those individuals come together to solve a community’s problems. His favorite projects are typically underground stormwater storage systems. The following images are from recent projects he’s been working on.

Ethan Williams

“Changes during the construction phase are interesting and exciting to work through. It seems every day there are new challenges to overcome.”

Ethan is a member of our water and wastewater team who works out of our Morgantown, West Virginia, office. He typically arrives at a construction site before dawn, so that he can review plans before the contractor begins. He determines where the contractor will work that day and makes note of possible challenges that may arise installing sewer across utilities, roads or other existing structures. He also checks for field orders, change orders, and work change directives that have been issued to make sure he is up-to-date on any changes to the original plans that might affect that day’s work.

Throughout the day, he works alongside the contractor, observing progress and answering any questions the contractor may have about the design.

Throughout the day, he works alongside the contractor, observing progress and answering any questions the contractor may have about the design.

He also performs administrative duties like tracking material quantities, typing daily construction reports, and working on as-build drawings.

“The contractor works from dusk till dawn, so my workday is typically around 12-13 hours long,” Ethan says.

The best part of the job for Ethan is seeing an idea on paper come to life. “When you look at a set of prints, it’s hard to appreciate the work put into the design or the magnitude of a project until you experience the challenges faced in the field,” he says.

He was inspired to pursue a career in civil engineering and construction while serving active duty in the military. “I deployed overseas several times, and it was shocking to see the lack of infrastructure in many other countries compared to the United States,” he recalls. “It gave me a whole new appreciation for the quality of life we experience here in America, thanks to our roads, bridges, water and wastewater systems.”

Knowing the connection between infrastructure and quality of life, Ethan takes great pride in the way his work improves the lives of friends and family that live near the projects he’s completing: “I’ve witnessed firsthand numerous failing septic systems, and I have no doubt that the time and effort spent on the improvements we’re building will reduce negative environmental impacts for years to come.”

Reduce the Cost of MS4 Compliance and Pollutant Reduction Plans Through Cooperation

/in Insights-Local Government, Insights-Municipal, Insights-Water Resources, Uncategorized /by Judy Lincoln

Stormwater management has become a major priority for environmental agencies over the past decade, and communities are struggling to meet the increasing requirements to reduce stormwater pollutants and runoff volume. The cost is simply too high for many municipalities to bear alone, but it becomes much more manageable if municipalities can share the burden with their neighbors.

Take the Pollutant Reduction Plan requirement of the MS4 application as an example. If a municipality submits a Pollutant Reduction Plan on its own, it is limited to constructing BMPs within its own borders or the drainage way of its impaired streams, but DEP will generally accept the construction of BMPs anywhere within the watershed for an MS4 permit that is submitted by a regional cooperative. This means cooperating municipalities can install BMPs that yield the greatest pollutant load reduction for the lowest cost.

Usually the largest expense associated with BMP construction is the cost of acquiring land on which to build the BMP. An individual municipality may not have much land on which to build, particularly if it is an urban municipality in which most of the available land has already been developed. As a result, the municipality may be forced to implement a large number of BMPs that each provide only marginal individual benefit in order to meet the pollutant reduction goal. If a municipality submits a regional plan with other communities in the same watershed, it will have access to a much greater land area on which to build BMPs and a reduced need for right-of-way acquisition and easements. This allows the participating municipalities to build the most effective water quality measures in the places with the greatest need.

Any improvements in upstream water quality will lead to improvements in downstream water quality, so a municipality can still see improvements in its water quality using a watershed-based approach even if a particular BMP is not located within that municipality’s borders.

When BMPs are constructed on a watershed-wide basis, the construction cost is typically lower due to economies of scale, and the water quality results are better.

Herbert, Rowland & Grubic, Inc. (HRG) is working with the Wyoming Valley Sanitary Authority on a regional stormwater collaboration that includes 32 municipalities in Luzerne County. These municipalities intend to meet 70% of their sediment reduction goal with a single BMP: conversion of existing flood control levees into a constructed wetland with a sediment forebay and a meandering stream channel.

Regional cooperation can save municipalities money in other ways besides BMP construction. For example, the cost of preparing the Pollutant Reduction Plan itself will be much lower as a result of cooperation due to economies of scale.

Hiring a consultant to assist with pollutant reduction planning can cost thousands of dollars. If that cost is shared with 10 other municipalities, each individual municipality only has to pay a small portion.

It’s like sharing your first apartment with two roommates when you were in your 20s. The fixed cost of rent and utilities is the same whether one person lives there or three, but each person pays less if they can split that cost three ways (instead of renting their own individual apartments).

Stormwater management involves many fixed costs like the cost of owning equipment to clean out inlets or conduct outfall inspections.

Spreading those costs across a greater number of users means each user pays a smaller price for service.

Another way cooperation can reduce the cost of stormwater management is by giving municipalities increased purchasing power. Generally, you can negotiate lower unit costs for items when you buy them in larger quantities. For example, cooperating municipalities could replace or slip line several miles of pipe for a lower cost if the work was completed as part of a larger, regional project. These savings apply to the bidding of services, too. The municipalities working with the Wyoming Valley Sanitary Authority saved hundreds of thousands of dollars on base mapping (i.e. orthophotography, impervious area, etc.) by participating with WVSA under a single project (rather than having each municipality bid its own contract).

Municipalities have greater purchasing power when they cooperate on stormwater management solutions. For example, cooperating municipalities could slip line several miles of pipe for a lower cost if the work was completed as part of a larger, regional project.

A regional cooperative also has more borrowing power than a single municipality, and funding agencies are more likely to award a grant or loan to a regional project than one submitted by a single municipality. Funding agencies prefer regional projects because they believe regional cooperation streamlines costs, and politicians tend to support projects that benefit as large a constituent base as possible. A regional initiative should be tied together by legal agreements that assure the funding agency all funding will be properly administered. (These legal agreements are also required to meet DEP requirements for submission of a regional pollution reduction plan.)

This post is an excerpt from a longer article in the July-August-September issue of Keystone Water Quality Manager magazine. The article is focused on the cost savings communities enjoy by cooperating with regional partners on their stormwater management programs. Read the magazine for advice on finding partners for your stormwater management program or contact us to request a copy.

Erin G. Letavic, P.E., is the regional manager of civil engineering services in HRG’s Harrisburg office. She guides municipalities and cooperative groups throughout Pennsylvania through the management of their MS4 permits, provides grant application development and administration services, and provides retained engineering services to local government.

Adrienne Vicari, P.E. is the financial services practice area leader at Herbert, Rowland & Grubic, Inc. (HRG). She provides strategic financial planning and grant administration services to numerous municipal and municipal authority clients. She also serves as project manager for several projects involving the creation of stormwater authorities or the addition of stormwater to the charter of existing authorities throughout Pennsylvania.

National Surveyors’ Week Spotlight: Robert Quetot

/in Uncategorized /by Judy Lincoln It’s National Surveyors’ Week, and we’re shining the spotlight on some of our surveyor team members. Today’s spotlight: Robert Quetot.!

It’s National Surveyors’ Week, and we’re shining the spotlight on some of our surveyor team members. Today’s spotlight: Robert Quetot.!

Robert is a survey specialist and team leader for HRG’s Western Region, which includes Pittsburgh, Ohio and West Virginia. He has nine years of experience in boundary and topographic surveying, ALTA surveys, and construction layout. His projects have included natural gas well pads and pipelines, parks and recreational facilities, water lines, and a variety of real estate developments.

He earned his bachelor’s degree in civil engineering from Youngstown State University but became interested in surveying during an internship with the Columbiana County Engineer’s office. He was assigned to a survey crew and enjoyed the work so much he turned his attention to the surveying profession instead of engineering.

“I LOVE the outdoors,” he says. “Second to that, I enjoy being the first and last boots on the ground for most projects, watching them come to life. Surveyors are involved throughout many project phases.”

His favorite project was in Okeechobee, Florida, gathering topographic data for the existing Herbert Hoover Dike. At the end of a long winter that doesn’t want to end here in Pennsylvania, an assignment in Florida sounds like paradise, but it included its fair share of danger. Poisonous snakes, alligators, wild boar and even fire ants could have been lurking around the next palmetto.

“The adrenaline this brings made for an interesting experience,” Robert says.

Learn more about HRG’s surveying services and surveying experience.

Read Robert’s bio to learn more about his education and the types of projects he’s completed.

National Surveyors’ Week Spotlight: Mike Kreiger

/in Uncategorized /by Judy Lincoln It’s National Surveyors’ Week, and we’re shining the spotlight on some of our surveyor team members. First up: Mike Kreiger, P.L.S.!

It’s National Surveyors’ Week, and we’re shining the spotlight on some of our surveyor team members. First up: Mike Kreiger, P.L.S.!

Mike is a senior project manager in our Harrisburg office and former president of the Pennsylvania Society of Land Surveyors. He has more than 20 years of experience in the field, conducting a wide variety of surveys for roadway and bridge construction, commercial and residential development, and water and sewer system design. He also has extensive experience in rail line surveying.

His high school physics teacher encouraged him to consider a career as a surveyor. At the time, Mike said, “I had no idea what he was talking about, but it got the wheels spinning and set me in the right direction.”

As his responsibilities have changed, his love for surveying has evolved with them. In his early years, he enjoyed being outside. As he became more involved in highway layout, he appreciated the integral contribution his work makes to our infrastructure and the ability of people and goods to get where they need to go. As a senior surveyor, he enjoys developing land title surveys, helping real estate agents and attorneys secure millions of dollars in financing for their projects. (Mike authored an article for our Insights blog on changes to the ALTA Land Title Standards in January 2016.)

He has made many good memories over the years, but a career in the field is not without its risks. Mike keeps his sense of humor about the tougher assignments.

“There was once a time that I got sprayed by a skunk and returned to the office before going home for the day,” he recalls with a smile. “I loved the faces, but there were many office people that likely did not appreciate my humor.”

Of all the projects he’s completed over the years, he says his favorite is probably the coastal erosion prevention survey he performed for the Amy Corps of Engineers. “Sun, sand and surveying, who can ask for anything else?” he says of the project, which stretched 83 miles along the southern coast of Long Island from Jones Beach to Montauk Point. “It wasn’t all that we expected; there were no warm breezes coming off the ocean.” (Did we forget to mention the project started in March?)

Another favorite would be a construction layout survey for three miles of roadway approaching the PA Turnpike’s Susquehanna River Bridge.

But Mike will always hold a special place in his heart for another construction layout survey along a 5-mile stretch of Dauphin Relief Road. This $44 million construction project included 4-lane roadway, bridges, culverts, and retaining walls. If you’re ever in the area, Mike encourages you to take a ride on the “Kreiger Dip:” eastbound lanes N 40°22’5.71″ W 76°58’19.96”.

Learn more about HRG’s surveying services and surveying experience.

Read Mike’s bio to learn more about his education and experience.

Threet and Letavic Introduce a Girl to Engineering

/in Uncategorized /by Judy LincolnToday is Introduce a Girl to Engineering Day, and who better to talk about why girls should consider a career in engineering than two of the women engineers we have on staff here at HRG?

Erin Threet is the regional manager of our Lewisburg office and a project manager overseeing the design of water and wastewater systems. Her work primarily focuses on making sure people have access to clean water. Projects range from evaluating water supply sources, to designing treatment processes that make the water safe for drinking and designing the infrastructure that carries the water where it needs to go.

Erin Threet is the regional manager of our Lewisburg office and a project manager overseeing the design of water and wastewater systems. Her work primarily focuses on making sure people have access to clean water. Projects range from evaluating water supply sources, to designing treatment processes that make the water safe for drinking and designing the infrastructure that carries the water where it needs to go.

Erin Letavic is a project manager and team leader in the civil engineering group at HRG. She primarily works with local governments as their retained municipal engineer and as a consultant on environmental issues like water quality, stormwater management, permitting, and flood prevention. She also helps residential and commercial developers obtain environmental permitting for the construction of homes and business parks.

Erin Letavic is a project manager and team leader in the civil engineering group at HRG. She primarily works with local governments as their retained municipal engineer and as a consultant on environmental issues like water quality, stormwater management, permitting, and flood prevention. She also helps residential and commercial developers obtain environmental permitting for the construction of homes and business parks.

Threet is passionate about encouraging young women to pursue engineering as a career. “It’s a very challenging and rewarding career path,” she says. “You get to work with clients to solve their problems and then see those solutions implemented.”

Every year, Threet participates in a local event sponsored by Junior Achievement where high school students can explore different career paths and ask questions about what it’s like to work in that industry. She also returns to her alma mater Bucknell University on a regular basis to speak with young women about engineering careers.

She was exposed to the concept of water and wastewater treatment at a young age. Here she is in the dirt while her parents were doing work on the family’s septic system.

She was exposed to the concept of water and wastewater treatment at a young age. Here she is in the dirt while her parents were doing work on the family’s septic system.

Looking at the picture now, she says, “I think it’s funny because I design water and wastewater facilities, and I talk about septic systems more frequently than the average person.”

Family members who worked in the engineering field inspired Threet to join the profession. “I knew that I liked math and science, so it seemed like the right path for me,” she says.

Letavic also liked math and science as a young girl, and she loved to spend time outside. Now her job allows her to spend time in the field on environmental investigations or restoration projects.

Protecting and preserving the environment for people to enjoy is very important to her. “I grew up seeing the evolution of no recycling to curbside recycling programs popping up everywhere, so I wear my environmental stewardship hat when I solve stormwater problems.”

Threet and Letavic’s example shows that engineering is an ideal career path for young women who are problem-solvers and who care about environmental issues like clean water.

Find more resources for young women interested in the engineering profession on the DiscoverE website.

Regional Stormwater Plan to Save Taxpayers Money in Luzerne County

/in Insights-Environmental, Insights-Local Government, Insights-Municipal, Insights-Water Resources, Uncategorized /by Judy LincolnThis article is an excerpt from the December 2017 issue of The Authority, a magazine produced by the Pennsylvania Municipal Authorities Association (PMAA). It is the second in a series of 3 articles about an innovative approach to stormwater management and MS4 compliance being pioneered by 31 municipalities and the Wyoming Valley Sanitary Authority. You can read the first article here: How Municipalities in the Wyoming Valley Are Cutting Stormwater Costs by Up to 90% )

Thirty-one municipalities in Luzerne County are piloting a regional approach to MS4 compliance that may revolutionize the way Pennsylvania responds to the growing challenges posed by stormwater.

They have signed cooperative agreements with the Wyoming Valley Sanitary Authority, which will serve as MS4 permit coordinator for the entire region. In our previous post, we discussed the many ways a regional partnership can lower the cost of stormwater management for municipalities.

In this post, we’ll discuss how:

Cooperation benefits the taxpayer.

If regional cooperation lowers the cost of stormwater management, it stands to reason those cost savings will be passed on to the taxpayer. But, make no mistake, replacing aging infrastructure and constructing Best Management Practices will cost money, and that money will have to come from somewhere.

With municipal budgets already stretched to the limit, communities may have to consider new revenue sources. That could mean a tax increase or a stormwater fee.

Stormwater fees are generally a better deal for the average constituent. This is because a fee structure ensures everyone pays their fair share.

If taxes were raised to cover the cost of stormwater management, many property owners with large amounts of impervious area would be exempt: hospitals, schools, and other non-profit institutions. However, these institutions can sometimes be the biggest contributors to a community’s stormwater issues because stormwater runoff occurs when the water runs along impervious surfaces and cannot infiltrate the ground.

If stormwater management is paid for through a property tax increase, these non-profit organizations won’t pay for the services they’re using, but someone will have to, and that burden will fall on homeowners and small businesses.

Studies show time and again that the average homeowner would pay less for stormwater management if he or she were charged a stormwater fee than if the municipality raised property taxes.

The regional cooperation being pioneered by the Wyoming Valley Sanitary Authority is an especially good deal for local taxpayers: Our analysis showed that the average residential property owner will save 70 – 93% by paying a regional stormwater fee instead of paying an increased property tax.

The Wyoming Valley Sanitary Authority’s estimated stormwater fee is between $3.00 and $4.50 per month. This is lower than the other stormwater fees currently being paid throughout Pennsylvania, which average between $6.50 and $8.50 per month.

By using a regional approach, WVSA is able to lower costs beyond what an individual municipal authority could likely achieve. These numbers are even more impressive when you consider that the fees for most of the other municipal authorities included in the average above were calculated before taking 2018 MS4 permit requirements into account. Therefore, those communities may actually have to raise fees higher to meet the stricter requirements coming in the next permit cycle. WVSA’s estimated cost already accounts for the 2018 permit requirements.

Municipal leaders are stewards of the public’s money, but they are also stewards of the environment. In our next post, we’ll discuss how regional cooperation on stormwater management can more effectively keep our rivers and streams clean for drinking, agriculture, and recreation.

Jim Tomaine has more than 30 years of engineering experience. He holds a bachelor’s degree in civil engineering from The Pennsylvania State University and a master’s degree in business administration from Wilkes University. He is the executive director of the Wyoming Valley Sanitary Authority and has been at WVSA for twenty seven years. Prior to the WVSA, Mr. Tomaine worked in the private sector as a design engineer. He currently holds his A-1 Wastewater Treatment Plant Operators Certification in Pennsylvania and is also a registered professional engineer.

Adrienne Vicari is the financial services practice area leader at Herbert, Rowland & Grubic, Inc. (HRG). In this role, she has helped the firm provide strategic financial planning and grant administration services to numerous municipal and municipal authority clients. She is also serving as project manager for several projects involving the creation of stormwater authorities or the addition of stormwater to the charter of existing authorities throughout Pennsylvania.

Benefits of Utility Asset Management

/in Insights-Financial, Insights-Local Government, Insights-Municipal, Insights-Water & Wastewater, Uncategorized /by Judy LincolnAs our water systems continue to age past their useful life and utilities face increasing budget pressures, the terms asset management and capital improvement planning have become buzzwords in the industry. However, as utility managers struggle to squeeze as much out of their budgets as possible, it is hard for many of them to justify the additional expense associated with developing and implementing an asset management program. Just like with any other purchase, they want to be sure the benefits outweigh the cost. So what are the benefits of asset management and capital improvement planning?

Target budget dollars where they’re needed most and eliminate wasteful spending.

An asset management and capital improvement program helps you identify exactly what maintenance and repair work is necessary without guesswork. Why allocate money toward cleaning out pipes selected at random, when you could target that money to the pipes that need it most (and use the savings to accomplish other system goals)? Why replace pipes simply because of age when they may be in perfectly good condition? Many factors besides age can cause the deterioration of infrastructure.

Photo by TheeErin. Published via a Creative Commons license.

Minimize Risk

Knowing which infrastructure is most likely to fail (and correcting deficiencies before it does) can save you major expenses later in the form of property claims, water loss, etc. Knowing which failures would be the most catastrophic helps you target money toward their prevention as a first priority. With the budget limitations of municipal utility management, you might not be able to prevent every system failure, so it’s important to know which ones have the potential to cause the most financial damage and impact the most customers. This way, you can focus your efforts on preventing those first. If a failure does occur, a good asset management plan will include a proactive response plan, allowing you to respond quicker and more efficiently (thereby reducing damage and disruption).

Maximize Returns

Asset management and capital improvement planning is all about proactively investing in measures to extend the life of your infrastructure. These small investments can extend the life of an asset by several years. Over time, the money you save delaying replacement will far surpass the money you spent to maintain the asset, and your customers will have enjoyed better, more consistent service for this lower cost.

Promote Sustainability

Finding and detecting failures in the system like leaks can prevent water loss and the wasted energy consumed to treat water that never makes it to a customer.

Optimize Customer Service and Satisfaction

Proactively maintaining your assets ensures they function at peak performance for a longer period of time and are replaced before they fail. This means your customers receive top quality service without disruption and are happier for it. In addition, many asset management solutions include optional customer service applications that make it easier for customers to submit service requests and track them to completion.

Justify Your Rates

Rate increases are never popular with customers, but they are easier for them to accept when they are backed up with clear data showing exactly what improvements are needed and why.

Access grants and loans

Competition for funding is fierce, and government agencies are under pressure to make sure the money they invest is used wisely. As a result, they’re more likely to award funds to utilities who have clear documentation of the project need, its benefits, and a plan for getting it built, operating it, and maintaining it at optimum levels over time.

Know your worth

Many utilities have been considering the option of leasing or selling their assets as a response to growing financial obligations in the public sector. A comprehensive asset management system provides documentation of the value of your assets, so you can ensure you are in a position to negotiate the best possible deal for you and your customers. Potential investors will be more comfortable making a significant investment if they fully understand the value and the risks they’re assuming. (For more Insight into the utility leasing trend, see our article on calculating fair annual rental value.)

Every manager must take careful stock of his revenue and his expenses, but not all expenses are created alike. There is a difference between a cost and an investment, and asset management is clearly an investment in your utility’s future. In essence, it helps you provide better service at a lower cost with reduced risk and improved financing options. How many investments can you make that provide that kind of return?

GUIDE: How An Infrastructure Bank Eliminates the Obstacles to Local Infrastructure Repair

/in Uncategorized /by Judy Lincoln

Local government officials are increasingly listing infrastructure repair and replacement as a top priority for their community, and a county infrastructure bank can help.

Deteriorating roads, bridges and pipes present a safety risk and hamper economic development, but local government budgets are being besieged by rising costs and federal mandates. An innovative solution for infrastructure funding is needed to stretch public dollars further.

County Infrastructure Banks make projects more affordable for local governments and provide them with expert guidance through complicated design and construction processes.

Most municipalities struggle to find the money they need to repair or replace their infrastructure. Many also have little or no experience managing major infrastructure projects, and they can easily be overwhelmed by the complexities of the regulations and permit requirements that govern this work. This can lead to mistakes that delay the schedule or increase costs unnecessarily.

Dauphin County has found a solution to both of these problems with their award-winning Dauphin County Infrastructure Bank program.

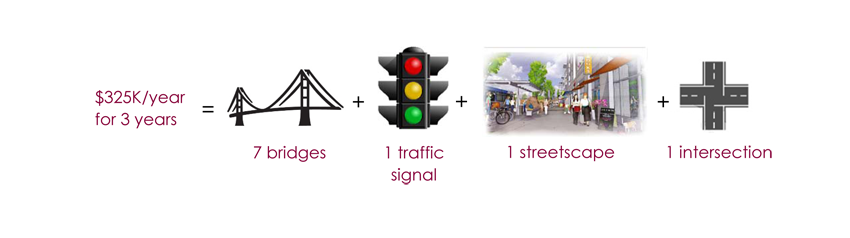

The county created its own financing program, using a small annual surplus of $325,000 per year in Liquid Fuels money. This small amount of money would not have been enough to fund even one single-span bridge replacement in today’s construction market, but their innovative infrastructure bank program has multiplied the impact of this seed money into more than 10 projects in just three years!

The county uses this money to subsidize loans from other sources, so that their local governments and private sector recipients can receive the funding at unbeatably low interest rates. It also manages the construction process to take advantage of economies of scale and ensure work is completed efficiently. (Loan recipients are offered optional engineering and design support, as well.) As applicants repay their loans, the bank funds are replenished, and the cycle can begin again with new applicants, creating a self-renewing, permanent funding source.

This program has been featured on the Governing magazine website and has been honored by both the National Association of County Officials and the Pennsylvania Department of Community and Economic Development. Learn how the program works:

With an infrastructure bank program like Dauphin County’s, county officials have a renewable funding source that can:

- Multiply the return on a small investment: completing several projects for less than the cost of one.

- Provide both funding and project delivery support to municipalities that otherwise wouldn’t have the resources or staff to complete complex infrastructure improvements.

- Make infrastructure more affordable by offering loans with unbeatably low interest rates to local municipalities and private firms.

- Promote economic growth.

- Target money to long-term, strategic planning goals for the region.

Learn how an infrastructure bank can make infrastructure repair easier and more affordable.

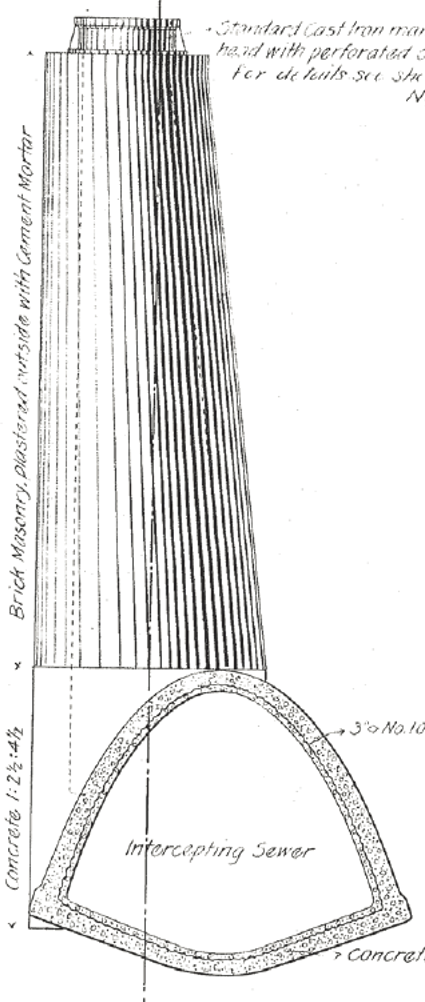

Assessing the Condition of Large Sewers

/in Insights-Water & Wastewater, Uncategorized /by Judy Lincoln Determining the condition of large sewers can be challenging, but multiple tools are available to help. This article, which was published in the October 2015 issue of Keystone Water Quality Manager magazine, provides a brief review of large sewer condition assessment tools and gives some guidance in deciding which to use.

Determining the condition of large sewers can be challenging, but multiple tools are available to help. This article, which was published in the October 2015 issue of Keystone Water Quality Manager magazine, provides a brief review of large sewer condition assessment tools and gives some guidance in deciding which to use.

Knowing the condition of your sewer system now can save you major headaches (and money) down the line. The investment you make today in conducting regular inspections of your pipes and pump stations will help you avoid emergencies like burst pipes and sewer overflows tomorrow, but it will also help you make better decisions about where to allocate limited revenues in terms of maintenance, repairs, and replacements.

Even though the investment in a condition assessment is worthwhile, you want to make sure you spend those assessment dollars wisely and get the data you need in the best possible quality for the lowest possible cost. Many tools are available, and each one is suited to particular needs. Which tool is right for your system? Let’s take a look at the strengths and limitations of some of the most popular methods of sewer inspection available today.

Knowing What Each Tool Can Do

1. Zoom Camera

A handheld or truck-mounted zoom camera is a great tool for quickly assessing the condition of large sewers. A zoom camera enables you to see for several hundred feet down the sewer line, but the view is limited by any obstruction to line of sight (such as grease, cobwebs, debris or a deflection in the sewer). In addition, the camera will only allow you to see above the water level.

2. Acoustic Assessment

Another quick assessment method is the use of acoustics. The ability for sound to pass through the sewer provides an indication of whether a blockage exists or not. However, it is not a complete assessment and will require some additional inspection work. Still, an acoustic assessment can cost about a quarter of the price of basic closed circuit television, so it can be used to save money by focusing more expensive data collection methods only on areas the acoustic assessment has identified to have potential blockages (as opposed to using a more expensive, but more thorough tool throughout the entire system).

3. Closed Circuit Television (CCTV)

CCTV has been used for many years to evaluate sewers, and it can be customized to the needs of your unique system because of the different types of cameras and vehicles that are available. A conventional pan and tilt camera may be sufficient for some pipes, but a fish-eye type camera lens can be used for a virtual pan and tilt that is somewhat more comprehensive.

CCTV provides a visual assessment of the sewer, but it can also be helpful in identifying buried manholes or revealing other unknowns in the connectivity of the sewer system.

In the past, it was a challenge to obtain sufficient lighting to get a clear picture of large sewers (see figure on the right), but new technology solves this problem by using a strobe light and stitching a series of images together, rather than recording continuous video.

4. Sonar

While some tools like the zoom camera cannot provide data on the condition of pipes below the water surface, sonar can. Therefore, it is useful for identifying debris and sensing connections below water level. However, some water must be in the sewer for the use of sonar to be possible.

5. Laser Profiling

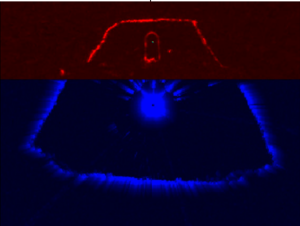

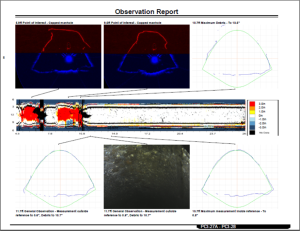

Laser profiling can reveal buried manholes or other connections to the sewer that may not have been realized and can also be used to assess pipe wall loss (as long as the original sewer size information is available and can be entered into the software). However, like the zoom camera, laser profiling can only be used to see above the water level. Therefore, it’s wise to combine it with sonar and CCTV in order to get a complete assessment of the sewer condition, as seen in the figure on the right. (The red shows results from the laser, while the blue shows results from sonar.) For a recent project involving 70,000 feet of sewer, the cost to use these three tools together was approximately $5-6 per foot.

6. LIDAR (3D Laser)

LIDAR is an advanced technology alternative to standard visual and photographic inspection methods. It uses 3D optical scanners to collect simultaneous data and images, which can be used to produce a 3D model of the sewer. This model can then be used to measure, identify deficiencies, and make recommendations for rehabilitation or replacement. It can also be used in 3D infrastructure system modeling and management applications when combined with equally accurate pipe and structure positional data. One instance 3D data is especially useful is in manufacturing the lining for a bend in a sewer.

As an advanced technology, LIDAR provides more comprehensive data than a zoom camera or CCTV inspection could. As an added bonus, the optical scanners are typically inserted into the sewer from the surface, eliminating the need for a person to enter the confined space of the sewer and the associated dangers they could encounter.

7. H2S Gas Sensor

An H2S Gas Sensor is helpful in cases where there is concern about corrosion. The sensor can be mounted on a multi-sensor platform to provide additional insight into the state of the sewer.

8. Gyroscopic mapping

Gyroscopic mapping is used to obtain X-Y-Z coordinates of the sewer along its length, so it’s helpful for identifying the location of bends or changes in elevation. However, this tool requires known X-Y-Z coordinates at the starting and ending points of a sewer.

For large sewers, a small pipe needs to be pulled through the large pipe as a host for the probe, leading to some limitations in the information gained. However, this tool can be useful for facilities such as force mains where changes in direction are often not seen from the surface.

9. In-pipe Ground Penetrating Radar (GPR)

GPR inside the pipe gives insight beyond the sewer itself. It can reveal void spaces outside the sewer line, such as may be caused by infiltration. It can also shed light on the thickness of concrete covering rebar in the sewer.

Deciding Which Tool is Right for You

With a clearer picture of what each tool can and cannot do, you’re better prepared to decide which one will produce the best results for your system. In doing so, here are some things you should consider:

1. Understand your goals.

Consider what you want to gain from the assessment. For example:

If you know the sewer segment has concerns and has bends in it, then 3D LIDAR may be desirable as a means of mapping the sewer.

If blockages are your concern, acoustic rapid assessment may be a good starting point to help narrow the focus on runs where you want to perform further evaluation.

If you have seen evidence of corrosion in manholes and have a concrete pipe, an H2S sensor may be in order.

If you want information on the whole pipe and cannot bypass the flows, you will need to supplement a technology like CCTV with sonar in order to see below the water surface.

When defining your goals, be sure to solicit the input of all levels of staff and the ways they can benefit from the data.

2. Consider combining technologies to address different needs.

Each tool described here has strengths and limitations, so no technology is perfect for all conditions. Laser profiling and sonar can be combined to get thorough data above and below the water surface. An acoustic assessment can be used as a preliminary method in order to identify any blocked pipes that require more detailed assessments. An H2S gas sensor may be needed for pipes that may have corrosion, but you may have pipes of varying material throughout your system and may not need to pay for this technology everywhere. By working with a knowledgeable consultant, you can customize a plan using several different technologies only where they are needed in order to maximize the use of your budget resources.

3. Recognize that special equipment availability may affect your schedule.

Specialized equipment is not as readily available as basic equipment, so, if quick turnaround is necessary, you may want to plan your schedule around any specialty equipment needs.

4. Understand the sewer material being investigated.

If the sewer is concrete, corrosion is a real concern, so an H2S gas sensor or laser profiling may be needed. (This is not the case if the sewer is vitrified clay.)

5. Consider the ground surface.

Is there evidence of settlement on the surface near sewer lines? If so, perhaps in-pipe GPR should be considered to look for voids that have developed around the sewer.

6. Recognize your flows.

Some of the tools described here have specific water flow requirements. For example, CCTV and laser profiling require head space above the water to be effective, but sonar needs a certain depth of water over the bottom of the sewer (as well as any debris present) in order to be successful. Therefore, you will need to coordinate with appropriate staff to implement a means of controlling the flow of water through these lines.

Water flow also impacts the types of vehicles used to carry the various tools through the sewer. Depending on your flows, a crawler may work well, or a float platform may be more suitable. Wheels can be put on float platforms, so additional space is needed for clearance.

7. Plan for the unexpected.

As much as you try to consider every goal and every possible need, each job involves surprises. (If you knew exactly what you’d find in the pipes, you wouldn’t need an inspection, after all, would you?)

That’s why you should design a plan that is flexible for changing circumstances and build extra time into your schedule. Decide ahead of time what will be done if a buried manhole or substantial debris is found: Will you uncover the manhole now? Will you clean the debris out right away or just note it in the report?

The vehicles carrying the inspection tools can often travel thousands of feet if there are no drops or other concerns, so you may not need to access every single manhole during a condition assessment. However, you should still have a method in place for identifying each manhole in case needs change. (Also, individually identifying each manhole – even those not uncovered for access – is essential for logging the findings of your assessment in a report.)

Develop IDs for every manhole – even those you don’t plan to access — prior to inspection and have a plan for how to ID structures if one is found during the investigation. This can reduce confusion and make post-processing more efficient.

A thorough assessment of the condition of your sewers is crucial to optimizing system performance, determining maintenance and repair needs, and budgeting for the eventual replacement of aging infrastructure. It can also help you discover problems before they result in a system failure or reduced service to your customers. While inspections can cost thousands of dollars, they can save you thousands more if they prevent a sewer main backup or break (and the associated costs to repair the sewer and other infrastructure the break may have damaged). They also help you better target your cleaning and maintenance efforts to where the work is needed most.

In determining which technology to use for a condition assessment, you need to consider the materials of your pipes and the volume of flows through them, the goals you plan to accomplish, and your timeline for completing the work. Some tools like a zoom camera or acoustic assessment provide quick data but may need to be supplemented with other methods if blockages are found or more detail is needed. Other tools like laser profiling and CCTV will only provide data on the condition of pipes above the water line, so additional technologies like sonar will be needed to assess the pipes below water level. Some technologies like 3D LIDAR and gyroscopic mapping provide a high level of detail that may be necessary for certain specialized cases.

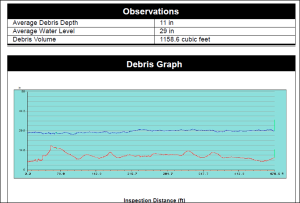

The figures above illustrate some meaningful findings from a condition assessment. The “shape” of the pipe resulting from sonar and laser profiling is compared with the design shape of the pipe in the figure on the left, indicating helpful information such as debris and uncovered manholes (the red spots). The quantity and distribution of debris as shown in the figure on the right will help in developing bidding documents for a cleaning project and getting better prices.

In order to provide the best possible data at an optimized price, it is wise to seek the counsel of an experienced professional who can customize a plan that uses several different technologies based on the varying conditions throughout your system.

With the right tools, you can ensure you get the data needed to keep your system functioning at optimum levels for all your customers for several years to come.

Matthew Cichy, P.E. is a water and wastewater senior project manager responsible for a variety of engineering tasks, including water and wastewater facilities planning, the design of water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants as well as construction administration, field inspections, financial consulting, and project management.

Matthew Cichy, P.E. is a water and wastewater senior project manager responsible for a variety of engineering tasks, including water and wastewater facilities planning, the design of water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants as well as construction administration, field inspections, financial consulting, and project management.

Bruce Hulshizer, P.E. is also a project manager in HRG’s water and wastewater service group. He has two decades of experience in civil engineering and is an active member of the Pennsylvania Water Environment Association, where he serves as their co-chair of the Collection System Committee for 2015.

Bruce Hulshizer, P.E. is also a project manager in HRG’s water and wastewater service group. He has two decades of experience in civil engineering and is an active member of the Pennsylvania Water Environment Association, where he serves as their co-chair of the Collection System Committee for 2015.

Learn more about our work with the Wyoming Valley Sanitary Authority in this 3-part series published in The Authority, a magazine published by the Pennsylvania Municipal Authorities Association.

Learn more about our work with the Wyoming Valley Sanitary Authority in this 3-part series published in The Authority, a magazine published by the Pennsylvania Municipal Authorities Association.