Each year, water and wastewater utilities send uncalculated dollars down the drain because of leaks and system failures, but asset management could provide the savings they need to respond to the creeping threats of aging infrastructure, water shortages, and increasingly stringent regulations.

Last year, UCLA filed a lawsuit against the Los Angeles Department of Water and Power for $13 million in damages sustained during a water main break on campus in 2014. This break released 20 million gallons of water onto Sunset Boulevard, flooding the street, campus buildings, and athletic facilities.

The lawsuit is just one of many claims the utility has received from people and businesses impacted by the water main failure; and it’s a reminder of the often hidden and forgotten costs utilities face when their infrastructure fails.

Every day, U.S. utilities produce 34 billion gallons of water, and 22% of it is lost through leaks. That’s billions of dollars in treatment, energy, labor and operations costs that cannot be recouped. These leaks cost the average utility more than $100,000 per year in revenue, but water main breaks like the one at UCLA can be even more costly.

Each year, there are approximately 240,000 water main breaks in the U.S., costing utilities an average $500,000 per break.

Much of our water and wastewater infrastructure is old and has far exceeded its life expectancy. Some pipes date back to the Civil War era! The cost to replace this infrastructure will be high, but, as these examples demonstrate, so is the cost of doing nothing.

As utilities struggle to budget for the replacement of aging systems, they continue to face increasing cost pressures from federal mandates. While the EPA establishes new limits on different contaminants (often requiring utilities to acquire new technology or improve their facilities), funding has not kept pace with these new demands. A report by the Water Infrastructure Network indicates that federal funding on water and wastewater systems has declined by more than 70% since 1980. As a result, local utilities have had to shift more of their revenue from operations and maintenance to new capital expenditures, leaving them even more ill-equipped to respond to an aging system.

At the same time, conservation efforts and improved technology have led many Americans to reduce their water consumption. While this is great for the environment, it translates into lower revenues for utilities – even as water acquisition costs increase (because utilities must turn to more expensive water sources once the least costly sources run dry).

With rising costs and shrinking revenues, utilities need to carefully manage every dollar to ensure the maximum return on their investment. The American Society of Civil Engineers estimates that the cost to make the improvements our water and wastewater system needs to keep functioning over the long term is more than $1 trillion. While there is plenty of work to be done, there is simply not enough funding to do it all at once. Therefore, ASCE recommends assessing the condition of every pipe and valve to determine the risks of failure and properly allocate funds where they are needed most. The need for asset management and capital improvement planning in the water utility industry has never been greater.

What is asset management?

Asset management is a systematic approach to minimizing the cost of owning, operating, and maintaining your infrastructure at acceptable levels of service.

It is not a computer system or GIS, though these are often valuable tools employed in an asset management program for record-keeping and data analysis. Depending on the needs of your utility, an effective asset management system could be as simple as an Excel spreadsheet or as robust as an enterprise level solution integrating all of your inventory, operations and maintenance, billing, and document management functions. The solution can include mobile interfaces for supporting field crews and even interactive applications to enhance and promote public interaction and transparency.

While utility managers often reject implementing a large-scale asset management program because they think it will cost too much, the truth is: asset management is an investment designed to cut inefficient or wasteful spending and stretch your budget further.

It is about optimizing how you spend your budget dollars in order to make sure they are providing the largest possible return on investment: reducing the life cycle costs of each asset you own while maximizing the service that asset provides over time.

A proper asset management and capital improvement program will help a utility identify areas where money is not being spent wisely and reallocate those funds where they can be most beneficial.

It will also help you recognize and evaluate options for keeping your assets functioning for a longer period of time, so that you don’t need to invest in expensive upgrades or replacements as frequently.

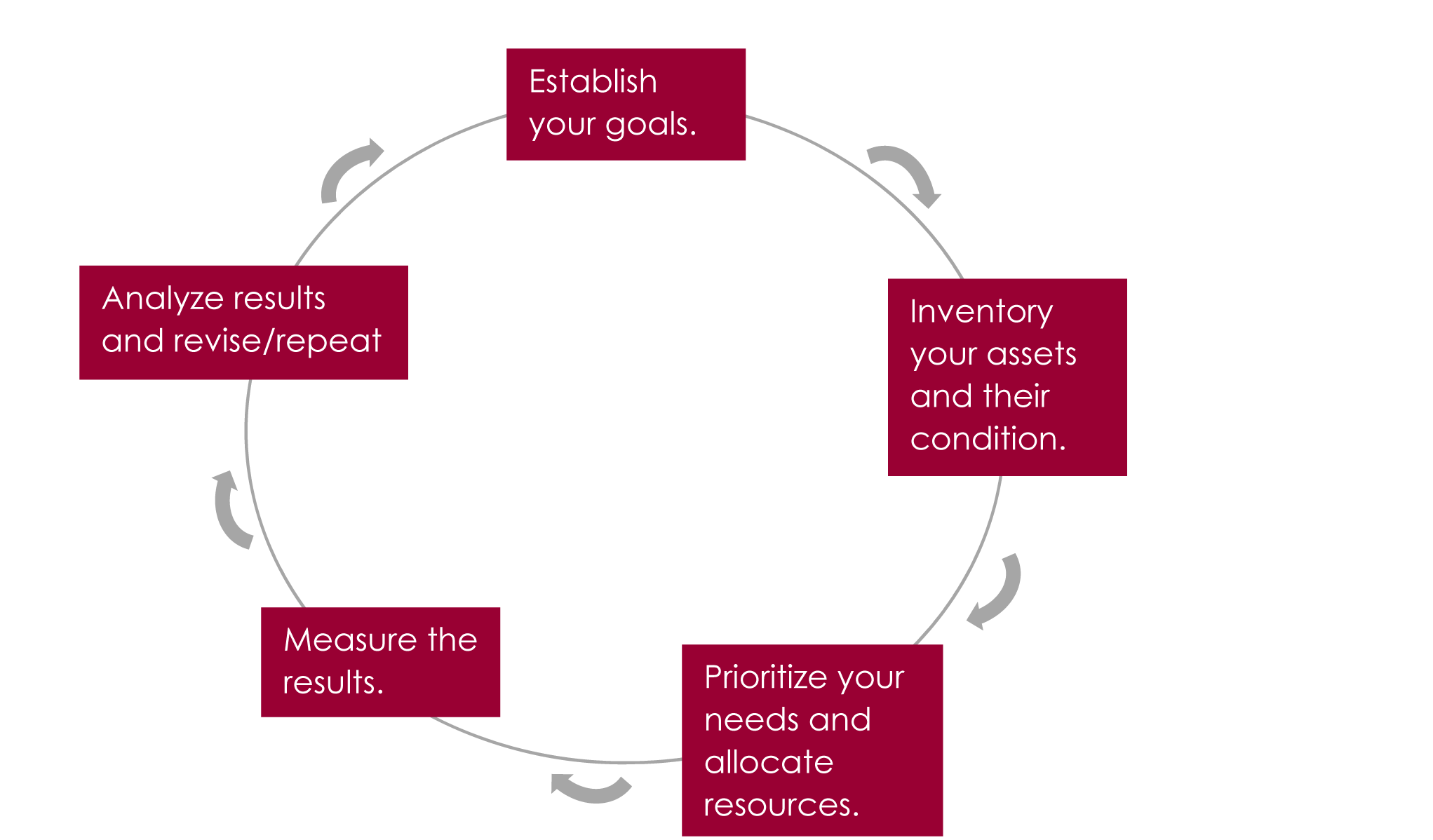

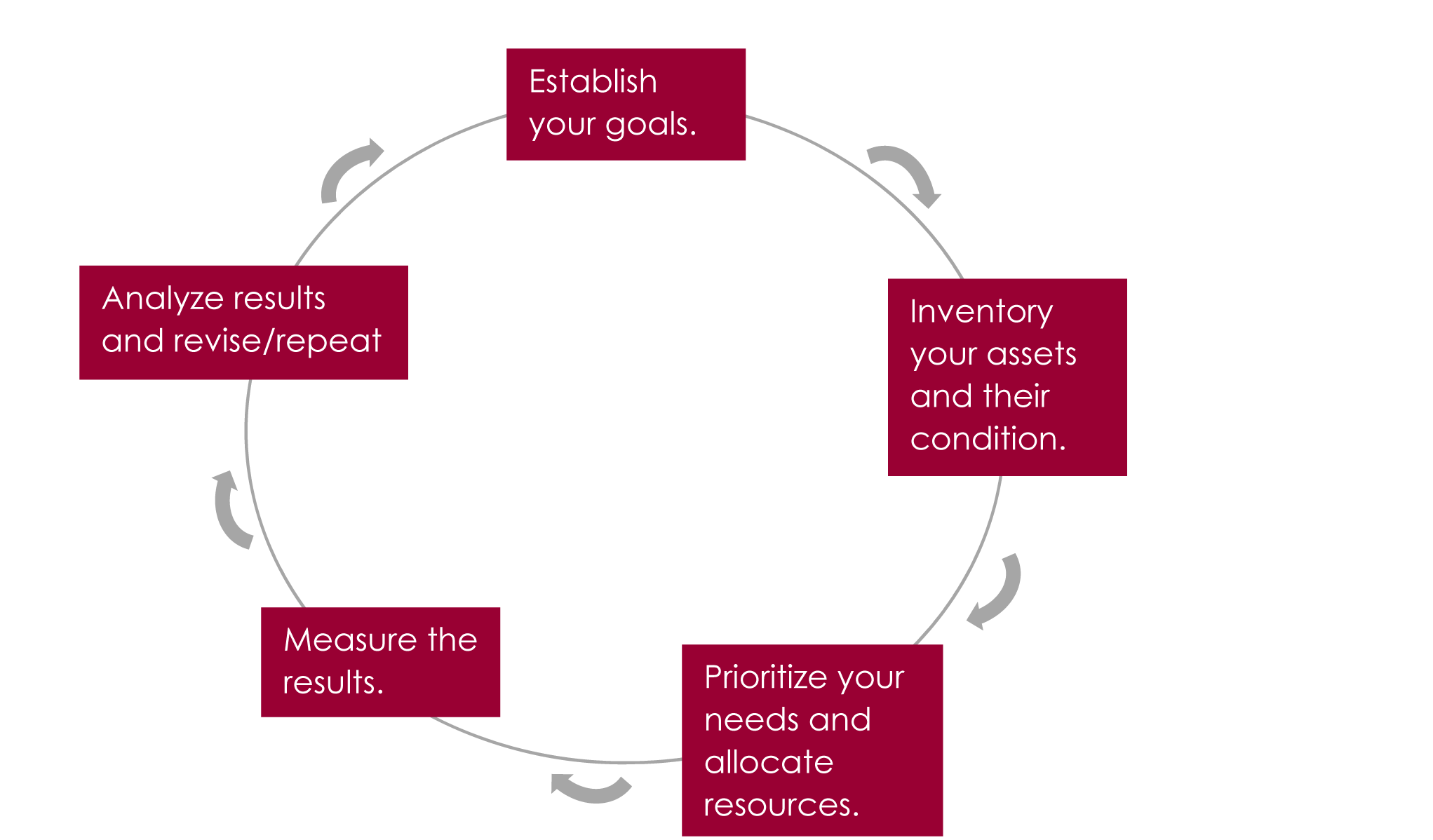

An asset management program involves:

Creating an inventory of what you have and its condition

Establishing your goals.

Prioritizing what’s most critical and directing resources to those needs first.

Measuring the results.

Analyzing those results and repeating or revising the cycle.

It is a circular process that never ends. Many things change over time: the condition of your assets, regulations and the business climate you operate in, the number of users you serve, etc. A good asset management and capital improvement program helps you plan for these changes in advance and respond proactively before they become threats to your bottom line.

Because of the tight financial constraints under which most utilities operate, they often take a reactive approach to budgeting for maintenance and replacements. As an asset fails, they make room in the budget to fix it or replace it, but this reactive approach will not be sustainable over the long-term. Our infrastructure is too old, and too much work will be needed to be able to pay for it all at once. Utilities need to plan for this inevitable future now, so that they can begin saving the money they will need in the coming decades.

Photo by Connie Ma. Published here under a Creative Commons license.

Proactive approach vs. Reactive: By monitoring the condition of your assets and planning for their maintenance and replacement in advance, you avoid the high costs associated with failures like this middle-of-the-night water main break.

Though the financial obligations associated with aging infrastructure, increasingly stringent regulation, and shrinking grant programs can seem overwhelming, asset management and capital improvement planning can help. Asset management helps you find the waste in your spending programs and put those dollars to better use. It helps you recognize potential threats to your system and minimize risk (thereby minimizing the financial damage those threats can do). It also helps you improve service to your customers and achieve buy-in from them when the case must be made for rate increases.

Investing in asset management and capital improvement planning can be hard to justify when utility budgets are stretched so thin, but the savings an asset management program can produce will more than pay for the program over time. Those savings, in fact, may be crucial to meeting the coming challenge of replacing our aging water systems and addressing the possibility of spreading water shortages.

In business, there’s an old saying: Sometimes you have to spend money to make money. With asset management, you spend money to save money.

HRG has extensive experience in asset management for municipal clients, particularly in the areas of sanitary and storm sewer systems. Read more about our asset management experience.

HRG’s water and wastewater practice area leader, Josh Fox, authored an article in the April issue of The Authority with Carlisle Borough’s director of public works, Mark Malarich. They talk about the success the borough has had using infiltration/inflow data to prioritize capital improvement needs and eliminate aging infrastructure. Over the past eight years, the borough has re-lined more than 46,000 linear feet of pipe and repaired, replaced or rehabilitated more than 200 manholes. Josh and Mark also talk about the importance of building flexibility into a capital improvement plan, and the ways they’ve been able to adjust their plans to respond to changing needs.

HRG’s water and wastewater practice area leader, Josh Fox, authored an article in the April issue of The Authority with Carlisle Borough’s director of public works, Mark Malarich. They talk about the success the borough has had using infiltration/inflow data to prioritize capital improvement needs and eliminate aging infrastructure. Over the past eight years, the borough has re-lined more than 46,000 linear feet of pipe and repaired, replaced or rehabilitated more than 200 manholes. Josh and Mark also talk about the importance of building flexibility into a capital improvement plan, and the ways they’ve been able to adjust their plans to respond to changing needs.

Matthew Cichy, P.E., is a senior project manager in HRG’s water and wastewater group. He is an expert in sewer system design, construction, and long-term asset management. His experience includes water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants.

Matthew Cichy, P.E., is a senior project manager in HRG’s water and wastewater group. He is an expert in sewer system design, construction, and long-term asset management. His experience includes water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants.