Assessing the Condition of Large Sewers

Determining the condition of large sewers can be challenging, but multiple tools are available to help. This article, which was published in the October 2015 issue of Keystone Water Quality Manager magazine, provides a brief review of large sewer condition assessment tools and gives some guidance in deciding which to use.

Determining the condition of large sewers can be challenging, but multiple tools are available to help. This article, which was published in the October 2015 issue of Keystone Water Quality Manager magazine, provides a brief review of large sewer condition assessment tools and gives some guidance in deciding which to use.

Knowing the condition of your sewer system now can save you major headaches (and money) down the line. The investment you make today in conducting regular inspections of your pipes and pump stations will help you avoid emergencies like burst pipes and sewer overflows tomorrow, but it will also help you make better decisions about where to allocate limited revenues in terms of maintenance, repairs, and replacements.

Even though the investment in a condition assessment is worthwhile, you want to make sure you spend those assessment dollars wisely and get the data you need in the best possible quality for the lowest possible cost. Many tools are available, and each one is suited to particular needs. Which tool is right for your system? Let’s take a look at the strengths and limitations of some of the most popular methods of sewer inspection available today.

Knowing What Each Tool Can Do

1. Zoom Camera

A handheld or truck-mounted zoom camera is a great tool for quickly assessing the condition of large sewers. A zoom camera enables you to see for several hundred feet down the sewer line, but the view is limited by any obstruction to line of sight (such as grease, cobwebs, debris or a deflection in the sewer). In addition, the camera will only allow you to see above the water level.

2. Acoustic Assessment

Another quick assessment method is the use of acoustics. The ability for sound to pass through the sewer provides an indication of whether a blockage exists or not. However, it is not a complete assessment and will require some additional inspection work. Still, an acoustic assessment can cost about a quarter of the price of basic closed circuit television, so it can be used to save money by focusing more expensive data collection methods only on areas the acoustic assessment has identified to have potential blockages (as opposed to using a more expensive, but more thorough tool throughout the entire system).

3. Closed Circuit Television (CCTV)

CCTV has been used for many years to evaluate sewers, and it can be customized to the needs of your unique system because of the different types of cameras and vehicles that are available. A conventional pan and tilt camera may be sufficient for some pipes, but a fish-eye type camera lens can be used for a virtual pan and tilt that is somewhat more comprehensive.

CCTV provides a visual assessment of the sewer, but it can also be helpful in identifying buried manholes or revealing other unknowns in the connectivity of the sewer system.

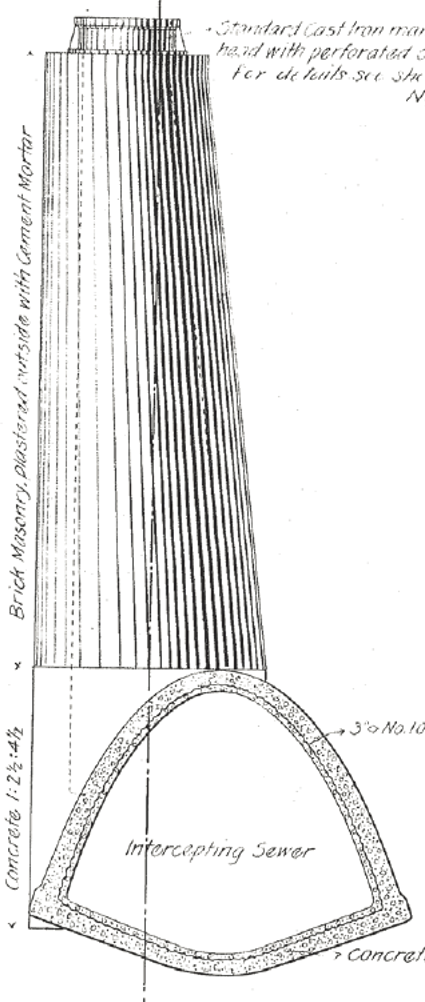

In the past, it was a challenge to obtain sufficient lighting to get a clear picture of large sewers (see figure on the right), but new technology solves this problem by using a strobe light and stitching a series of images together, rather than recording continuous video.

4. Sonar

While some tools like the zoom camera cannot provide data on the condition of pipes below the water surface, sonar can. Therefore, it is useful for identifying debris and sensing connections below water level. However, some water must be in the sewer for the use of sonar to be possible.

5. Laser Profiling

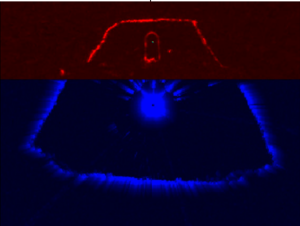

Laser profiling can reveal buried manholes or other connections to the sewer that may not have been realized and can also be used to assess pipe wall loss (as long as the original sewer size information is available and can be entered into the software). However, like the zoom camera, laser profiling can only be used to see above the water level. Therefore, it’s wise to combine it with sonar and CCTV in order to get a complete assessment of the sewer condition, as seen in the figure on the right. (The red shows results from the laser, while the blue shows results from sonar.) For a recent project involving 70,000 feet of sewer, the cost to use these three tools together was approximately $5-6 per foot.

6. LIDAR (3D Laser)

LIDAR is an advanced technology alternative to standard visual and photographic inspection methods. It uses 3D optical scanners to collect simultaneous data and images, which can be used to produce a 3D model of the sewer. This model can then be used to measure, identify deficiencies, and make recommendations for rehabilitation or replacement. It can also be used in 3D infrastructure system modeling and management applications when combined with equally accurate pipe and structure positional data. One instance 3D data is especially useful is in manufacturing the lining for a bend in a sewer.

As an advanced technology, LIDAR provides more comprehensive data than a zoom camera or CCTV inspection could. As an added bonus, the optical scanners are typically inserted into the sewer from the surface, eliminating the need for a person to enter the confined space of the sewer and the associated dangers they could encounter.

7. H2S Gas Sensor

An H2S Gas Sensor is helpful in cases where there is concern about corrosion. The sensor can be mounted on a multi-sensor platform to provide additional insight into the state of the sewer.

8. Gyroscopic mapping

Gyroscopic mapping is used to obtain X-Y-Z coordinates of the sewer along its length, so it’s helpful for identifying the location of bends or changes in elevation. However, this tool requires known X-Y-Z coordinates at the starting and ending points of a sewer.

For large sewers, a small pipe needs to be pulled through the large pipe as a host for the probe, leading to some limitations in the information gained. However, this tool can be useful for facilities such as force mains where changes in direction are often not seen from the surface.

9. In-pipe Ground Penetrating Radar (GPR)

GPR inside the pipe gives insight beyond the sewer itself. It can reveal void spaces outside the sewer line, such as may be caused by infiltration. It can also shed light on the thickness of concrete covering rebar in the sewer.

Deciding Which Tool is Right for You

With a clearer picture of what each tool can and cannot do, you’re better prepared to decide which one will produce the best results for your system. In doing so, here are some things you should consider:

1. Understand your goals.

Consider what you want to gain from the assessment. For example:

If you know the sewer segment has concerns and has bends in it, then 3D LIDAR may be desirable as a means of mapping the sewer.

If blockages are your concern, acoustic rapid assessment may be a good starting point to help narrow the focus on runs where you want to perform further evaluation.

If you have seen evidence of corrosion in manholes and have a concrete pipe, an H2S sensor may be in order.

If you want information on the whole pipe and cannot bypass the flows, you will need to supplement a technology like CCTV with sonar in order to see below the water surface.

When defining your goals, be sure to solicit the input of all levels of staff and the ways they can benefit from the data.

2. Consider combining technologies to address different needs.

Each tool described here has strengths and limitations, so no technology is perfect for all conditions. Laser profiling and sonar can be combined to get thorough data above and below the water surface. An acoustic assessment can be used as a preliminary method in order to identify any blocked pipes that require more detailed assessments. An H2S gas sensor may be needed for pipes that may have corrosion, but you may have pipes of varying material throughout your system and may not need to pay for this technology everywhere. By working with a knowledgeable consultant, you can customize a plan using several different technologies only where they are needed in order to maximize the use of your budget resources.

3. Recognize that special equipment availability may affect your schedule.

Specialized equipment is not as readily available as basic equipment, so, if quick turnaround is necessary, you may want to plan your schedule around any specialty equipment needs.

4. Understand the sewer material being investigated.

If the sewer is concrete, corrosion is a real concern, so an H2S gas sensor or laser profiling may be needed. (This is not the case if the sewer is vitrified clay.)

5. Consider the ground surface.

Is there evidence of settlement on the surface near sewer lines? If so, perhaps in-pipe GPR should be considered to look for voids that have developed around the sewer.

6. Recognize your flows.

Some of the tools described here have specific water flow requirements. For example, CCTV and laser profiling require head space above the water to be effective, but sonar needs a certain depth of water over the bottom of the sewer (as well as any debris present) in order to be successful. Therefore, you will need to coordinate with appropriate staff to implement a means of controlling the flow of water through these lines.

Water flow also impacts the types of vehicles used to carry the various tools through the sewer. Depending on your flows, a crawler may work well, or a float platform may be more suitable. Wheels can be put on float platforms, so additional space is needed for clearance.

7. Plan for the unexpected.

As much as you try to consider every goal and every possible need, each job involves surprises. (If you knew exactly what you’d find in the pipes, you wouldn’t need an inspection, after all, would you?)

That’s why you should design a plan that is flexible for changing circumstances and build extra time into your schedule. Decide ahead of time what will be done if a buried manhole or substantial debris is found: Will you uncover the manhole now? Will you clean the debris out right away or just note it in the report?

The vehicles carrying the inspection tools can often travel thousands of feet if there are no drops or other concerns, so you may not need to access every single manhole during a condition assessment. However, you should still have a method in place for identifying each manhole in case needs change. (Also, individually identifying each manhole – even those not uncovered for access – is essential for logging the findings of your assessment in a report.)

Develop IDs for every manhole – even those you don’t plan to access — prior to inspection and have a plan for how to ID structures if one is found during the investigation. This can reduce confusion and make post-processing more efficient.

A thorough assessment of the condition of your sewers is crucial to optimizing system performance, determining maintenance and repair needs, and budgeting for the eventual replacement of aging infrastructure. It can also help you discover problems before they result in a system failure or reduced service to your customers. While inspections can cost thousands of dollars, they can save you thousands more if they prevent a sewer main backup or break (and the associated costs to repair the sewer and other infrastructure the break may have damaged). They also help you better target your cleaning and maintenance efforts to where the work is needed most.

In determining which technology to use for a condition assessment, you need to consider the materials of your pipes and the volume of flows through them, the goals you plan to accomplish, and your timeline for completing the work. Some tools like a zoom camera or acoustic assessment provide quick data but may need to be supplemented with other methods if blockages are found or more detail is needed. Other tools like laser profiling and CCTV will only provide data on the condition of pipes above the water line, so additional technologies like sonar will be needed to assess the pipes below water level. Some technologies like 3D LIDAR and gyroscopic mapping provide a high level of detail that may be necessary for certain specialized cases.

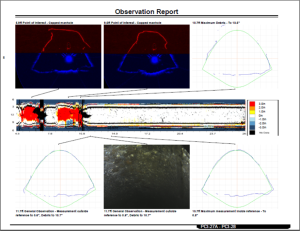

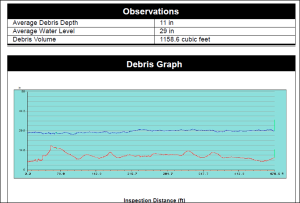

The figures above illustrate some meaningful findings from a condition assessment. The “shape” of the pipe resulting from sonar and laser profiling is compared with the design shape of the pipe in the figure on the left, indicating helpful information such as debris and uncovered manholes (the red spots). The quantity and distribution of debris as shown in the figure on the right will help in developing bidding documents for a cleaning project and getting better prices.

In order to provide the best possible data at an optimized price, it is wise to seek the counsel of an experienced professional who can customize a plan that uses several different technologies based on the varying conditions throughout your system.

With the right tools, you can ensure you get the data needed to keep your system functioning at optimum levels for all your customers for several years to come.

Matthew Cichy, P.E. is a water and wastewater senior project manager responsible for a variety of engineering tasks, including water and wastewater facilities planning, the design of water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants as well as construction administration, field inspections, financial consulting, and project management.

Matthew Cichy, P.E. is a water and wastewater senior project manager responsible for a variety of engineering tasks, including water and wastewater facilities planning, the design of water distribution systems, wastewater collection and conveyance systems, pumping stations, and water and wastewater treatment plants as well as construction administration, field inspections, financial consulting, and project management.

Bruce Hulshizer, P.E. is also a project manager in HRG’s water and wastewater service group. He has two decades of experience in civil engineering and is an active member of the Pennsylvania Water Environment Association, where he serves as their co-chair of the Collection System Committee for 2015.

Bruce Hulshizer, P.E. is also a project manager in HRG’s water and wastewater service group. He has two decades of experience in civil engineering and is an active member of the Pennsylvania Water Environment Association, where he serves as their co-chair of the Collection System Committee for 2015.